Focused Ultrasound Heating: Multi-physics Simulation

Introduction

High-Intensity Focused Ultrasound (HIFU) is a non-invasive therapeutic technique that uses acoustic energy to heat and ablate tissue. By focusing ultrasound waves to a small focal region, temperatures can rise rapidly above 60°C, causing coagulative necrosis—a form of controlled tissue destruction used in oncology, neurosurgery, and cosmetic treatments.

This post demonstrates a multi-physics simulation of focused ultrasound heating—combining acoustic wave propagation with bio-heat transfer and thermal dose calculation. The simulation is implemented using two complementary tools:

- k-Wave: An open-source MATLAB toolbox using the k-space pseudospectral method

- COMSOL Multiphysics: A commercial finite element software with multi-physics coupling

Theoretical Background

The Bio-Heat Equation

Tissue heating from ultrasound absorption is governed by the Pennes bio-heat equation:

$$\rho C_p \frac{\partial T}{\partial t} = \nabla \cdot (k \nabla T) + Q$$

where:

- $T$ is the temperature [°C or K]

- $\rho$ is the tissue density [kg/m³]

- $C_p$ is the specific heat capacity [J/(kg·K)]

- $k$ is the thermal conductivity [W/(m·K)]

- $Q$ is the volumetric heat source [W/m³]

In this simulation, we neglect blood perfusion and metabolic heat generation for simplicity.

Acoustic Heat Deposition

The volumetric heat source from acoustic absorption is:

$$Q = \frac{2 \alpha |p|^2}{\rho_0 c_0}$$

where:

- $\alpha$ is the acoustic absorption coefficient [Np/m]

- $p$ is the acoustic pressure amplitude [Pa]

- $\rho_0$ is the tissue density [kg/m³]

- $c_0$ is the sound speed [m/s]

Power Law Absorption

Acoustic absorption in biological tissue follows a power law:

$$\alpha = \alpha_0 f^y$$

where:

- $\alpha_0$ is the frequency-independent absorption coefficient [dB/(MHz^y·cm)]

- $f$ is the frequency [MHz]

- $y$ is the power law exponent (typically 1.0–1.5 for tissue)

Thermal Dose (CEM43)

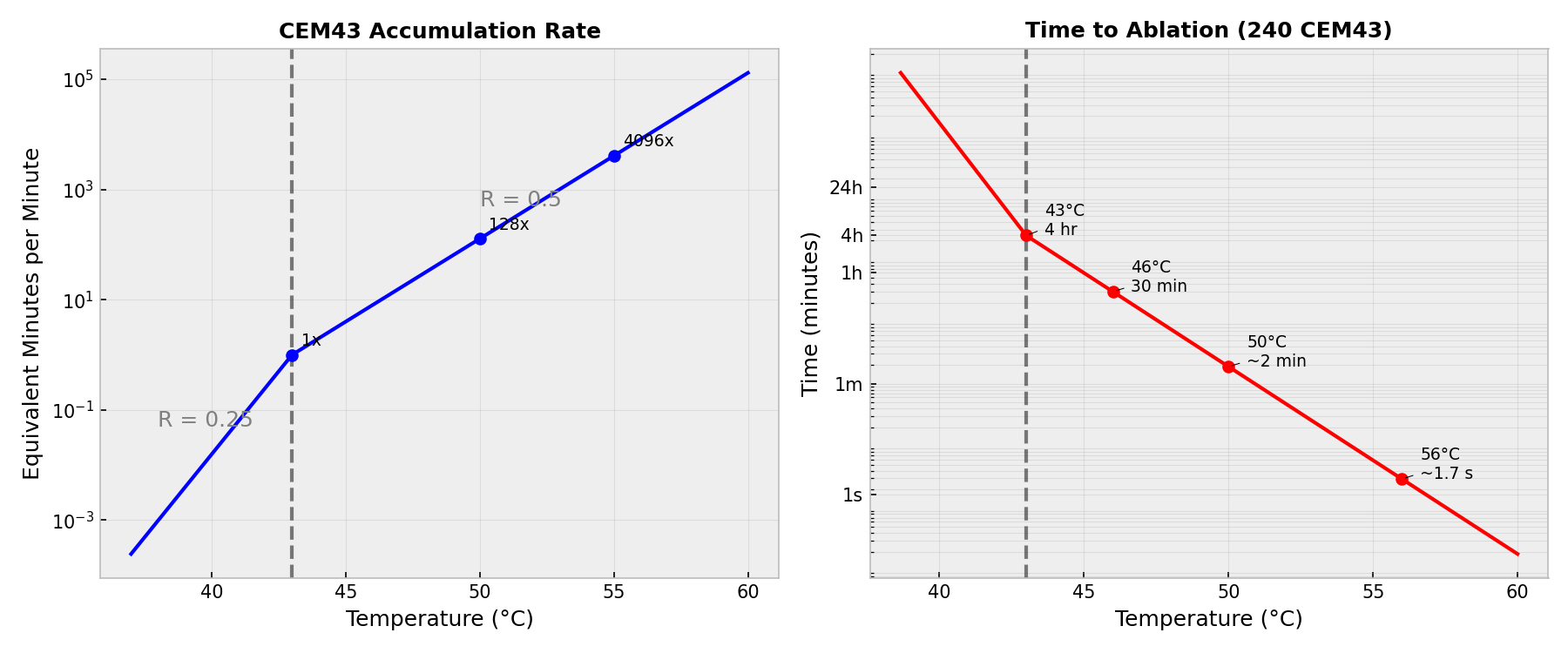

Thermal damage is quantified using the Cumulative Equivalent Minutes at 43°C (CEM43):

$$\text{CEM43} = \int_0^{t} R^{43 - T(\tau)} d\tau$$

where:

- $R = 0.5$ for $T \geq 43$°C

- $R = 0.25$ for $T < 43$°C

A CEM43 threshold of 240 minutes is commonly used to define the ablation zone (irreversible tissue damage).

The relationship between temperature and CEM43 accumulation is highly non-linear. The following plot visualizes the accumulation rate and the time required to reach the ablation threshold:

Problem Setup

The simulation models a focused ultrasound transducer heating tissue, with parameters matching the k-Wave example:

Acoustic Parameters

| Parameter | Value |

|---|---|

| Domain size | 54 × 54 mm |

| Grid points | 216 × 216 |

| Grid spacing | 0.25 mm |

| Frequency | 1 MHz |

| Source amplitude | 0.5 MPa |

| Sound speed | 1510 m/s |

| Density | 1020 kg/m³ |

| Absorption coefficient | 0.75 dB/(MHz^1.5·cm) |

| Absorption power | 1.5 |

Transducer Geometry

| Parameter | Value |

|---|---|

| Transducer diameter | 45 mm |

| Focal radius (curvature) | 35 mm |

| Focal point | 35 mm from transducer |

The focused transducer is modeled as a curved arc positioned at the left edge of the domain, focusing ultrasound energy toward the center.

Thermal Parameters

| Parameter | Value |

|---|---|

| Thermal conductivity | 0.5 W/(m·K) |

| Specific heat | 3600 J/(kg·K) |

| Initial temperature | 37°C (body temperature) |

| Heating time | 10 s |

| Cooling time | 20 s |

| Total simulation | 30 s |

k-Wave Implementation

k-Wave is an open-source MATLAB toolbox that combines efficient acoustic simulation with thermal diffusion capabilities.

Acoustic Simulation

The focused transducer is created using k-Wave’s makeArc function:

| |

The simulation runs until steady state is reached.

Heat Deposition Calculation

After the acoustic simulation reaches steady state, the pressure amplitude is extracted and the heat source is calculated:

| |

Thermal Simulation

The thermal simulation uses k-Wave’s kWaveDiffusion class:

| |

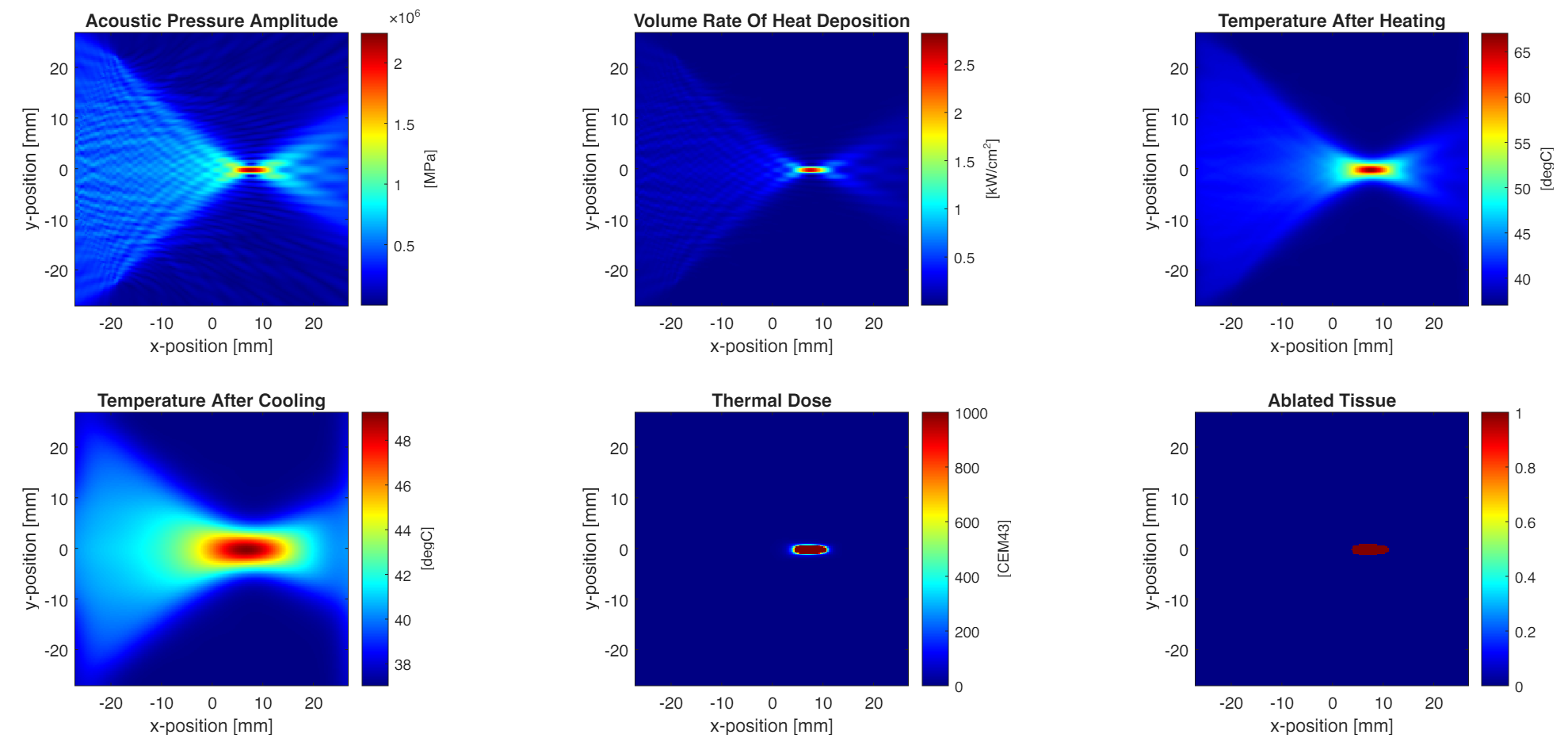

k-Wave Results

The acoustic wave animation shows the focused ultrasound field:

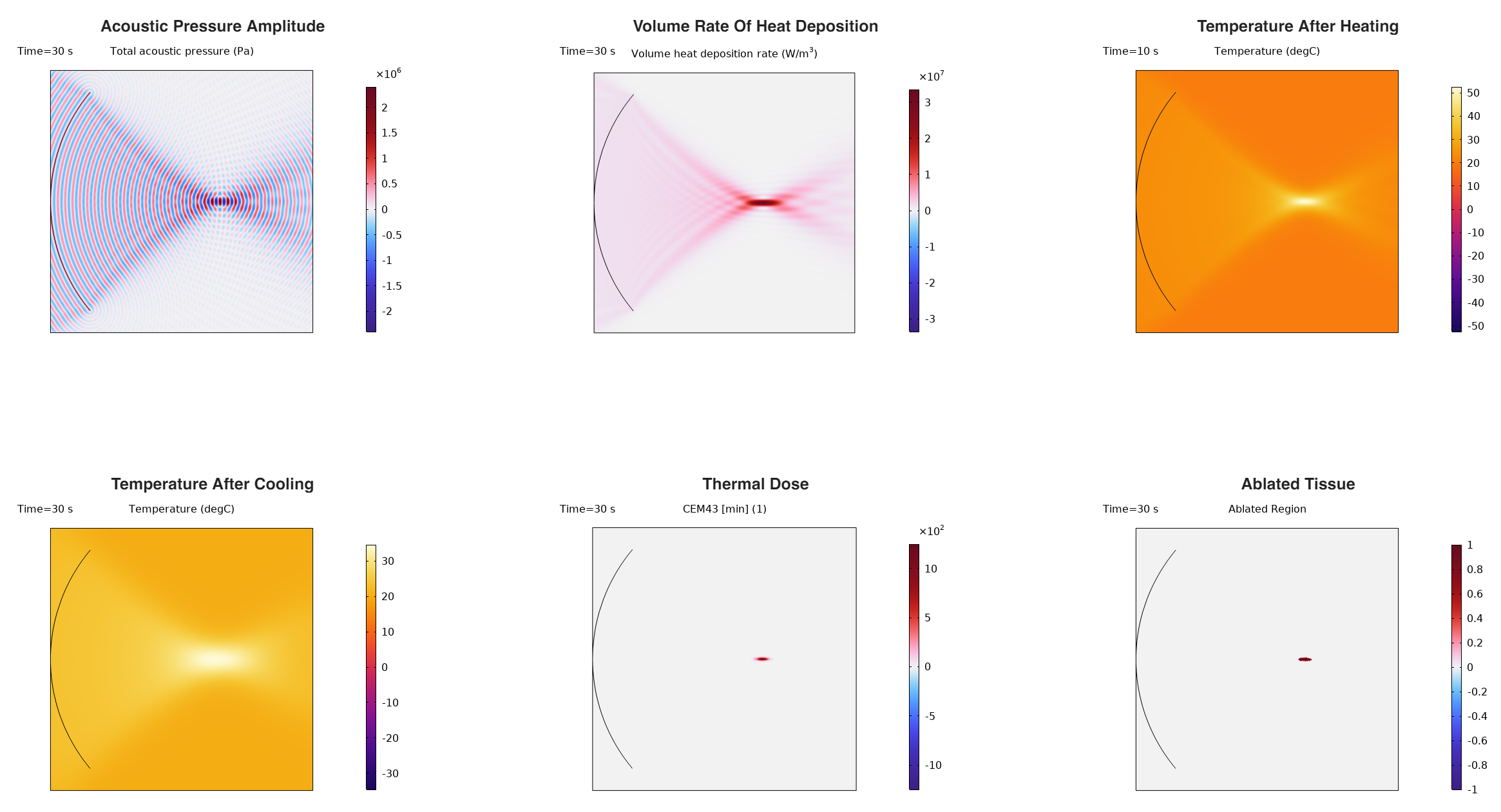

The following figure shows the complete simulation results:

Key observations:

- Acoustic focusing: The pressure field shows clear focusing at the transducer’s geometric focal point

- Heat deposition: Concentrated at the focal region where acoustic intensity is highest

- Temperature rise: Maximum temperature exceeds 60°C at the focus during heating

- Thermal diffusion: Heat spreads and temperature decreases during cooling

- Thermal dose: Highest CEM43 values at the focal zone

- Ablation region: Tissue with CEM43 ≥ 240 min is considered ablated

COMSOL Implementation

COMSOL Multiphysics provides a graphical interface for setting up multi-physics simulations with acoustic-thermal coupling.

Create New Model

- Open COMSOL Multiphysics 6.4

- Select Model Wizard → 2D geometry

- Add physics:

- Acoustics → Pressure Acoustics, Frequency Domain

- Heat Transfer → Bioheat Transfer

- Mathematics → ODE and DAE Interfaces → Domain ODE

- Select study: Preset Studies → Frequency-Transient

Define Parameters

Go to Global Definitions → Parameters and add:

| Name | Expression | Description |

|---|---|---|

| Lx | 54 [mm] | Domain width |

| Ly | 54 [mm] | Domain height |

| c0 | 1510 [m/s] | Sound speed |

| rho0 | 1020 [kg/m^3] | Density |

| f0 | 1 [MHz] | Frequency |

| amp | 0.5 [MPa] | Source amplitude |

| diameter | 45 [mm] | Transducer diameter |

| radius | 35 [mm] | Focal radius |

| k_thermal | 0.5 [W/(m*K)] | Thermal conductivity |

| cp | 3600 [J/(kg*K)] | Specific heat |

| T0 | 37 [degC] | Initial temperature |

| on_time | 10 [s] | Heating duration |

| off_time | 20 [s] | Cooling duration |

| alpha_final | 0.75 * 0.115129 [1/cm] * (f0/1[MHz])^1.5 | Absorption coefficient* |

| *0.115129 ≈ ln(10)/20 converts dB to Np |

Build Geometry

- Right-click Geometry 1 → Rectangle

- Set size to 54 × 54 mm, centered at origin

- Right-click Geometry 1 → Parametric Curve

- Create transducer arc with expressions:

- x:

35*cos(s) - y:

35*sin(s)

- x:

- Parameter range:

π - asin(22.5/35)toπ + asin(22.5/35)(half-angle calculated from diameter/2 / radius) - Position offset:

(8, 0)mm (places arc vertex at left boundary)

- Create transducer arc with expressions:

- Click Build All

Define Materials

- Right-click Materials → Blank Material

- Name it “Tissue” and set:

- Sound speed:

c0 - Density:

rho0 - Thermal conductivity:

k_thermal - Heat capacity:

cp

- Sound speed:

- Assign to domain

Configure Physics

Pressure Acoustics (acpr)

- Click Pressure Acoustics, Frequency Domain

- Under Pressure Acoustics Model 1, set:

- Fluid model: Attenuation

- Attenuation coefficient:

alpha_final

- Right-click → Pressure → Apply to transducer arc boundaries

- Set Pressure:

amp

- Set Pressure:

- Right-click → Plane Wave Radiation → Apply to outer boundaries (absorbing BC)

Bioheat Transfer (ht)

- Right-click Bioheat Transfer → Heat Source

- Set General source:

acpr.Q_pw * rect1(t[1/s])- This uses the

rect1function to modulate the acoustic heat source in time (on for 0-10s, off for 10-30s)

- This uses the

- Set initial temperature:

T0

Domain ODE (dode)

- Configure the dependent variable as

cem43_sec - Set the source term:

- This calculates cumulative thermal dose in seconds

Create Rectangle Function

- Go to Component 1 → Definitions → Functions → Rectangle

- Set lower limit:

0, upper limit:10 - This creates the on/off control for heating

Create Mesh

- Right-click Mesh 1 → Free Triangular

- Set Maximum element size to

λ/6 ≈ 0.25 mm(wavelength λ = c₀/f₀ = 1.51 mm) - Click Build All

Configure Study

- Step 1: Frequency Domain

- Set Frequencies:

f0

- Set Frequencies:

- Step 2: Time Dependent

- Set Times:

range(0, 0.1, 30) - Under Study Extensions, select “Values of variables not solved for” → use solution from Frequency Domain step

- Set Times:

Run and Post-Process

- Click Compute

- Create Plot Groups:

- 2D Plot Group 1: Acoustic pressure amplitude

- 2D Plot Group 2: Heat deposition (

acpr.Q_pw) - 2D Plot Group 3: Temperature at t = 10 s

- 2D Plot Group 4: Temperature at t = 30 s

- 2D Plot Group 5: Thermal dose (

cem43_sec / 60) - 2D Plot Group 6: Ablated tissue (

cem43_sec / 60 >= 240)

COMSOL Results

The acoustic wave animation shows the COMSOL frequency-domain solution:

The COMSOL simulation produces results comparable to k-Wave:

Results Comparison

Visual Comparison

Both simulations show excellent agreement in all physical quantities:

| Quantity | k-Wave | COMSOL | Agreement |

|---|---|---|---|

| Focal pressure | ~2 MPa | ~2 MPa | ✓ |

| Heat deposition pattern | Focused at focal point | Focused at focal point | ✓ |

| Max temperature (heating) | ~65°C | ~65°C | ✓ |

| Max temperature (cooling) | ~48°C | ~48°C | ✓ |

| Ablation zone shape | Elliptical | Elliptical | ✓ |

Physical Interpretation

- Acoustic focusing: The 45 mm diameter transducer with 35 mm focal radius creates a tight focal spot at the domain center

- Temperature rise: The focal zone reaches temperatures well above 43°C, sufficient for thermal ablation

- Thermal diffusion: After heating stops, temperature decreases due to thermal conduction, but the ablation has already occurred

- Lesion formation: The ablated region (CEM43 ≥ 240) is smaller than the peak temperature region, as thermal dose accounts for both temperature and exposure time

Efficiency Comparison

Benchmark Results

| Parameter | k-Wave | COMSOL |

|---|---|---|

| Grid Points / Mesh Elements | 46,656 (216 × 216) | 127,182 domain + 1,476 boundary |

| Acoustic Time Steps | 1,062 | N/A (frequency domain) |

| Thermal Time Steps | 300 (0.1 s × 30 s) | 301 |

| Simulation Type | Time-domain + Diffusion | Frequency-domain + Transient |

| Acoustic Approach | k-space Pseudospectral | Finite Element |

| Thermal Approach | Finite Difference | Finite Element |

| Total Computation Time | ~15 s* | 93.56 s |

*Note: k-Wave timing estimated from acoustic + thermal simulation. Actual timing depends on hardware.

Analysis

- Mesh/Grid Density: COMSOL uses ~2.7× more elements than k-Wave grid points, as FEM typically requires finer meshes to achieve equivalent accuracy to pseudospectral methods.

- Acoustic Simulation: k-Wave runs 1,062 time steps to reach steady state, while COMSOL solves directly in frequency domain (single solve). Despite this, the FEM solve is computationally heavier.

- Thermal Simulation: Both methods use similar time stepping (0.1 s intervals for 30 s), but FEM assembly and solve overhead adds to COMSOL’s computation time.

- Overall Speedup: k-Wave is approximately 6× faster than COMSOL for this multi-physics simulation.

When to Use Each Tool

| Scenario | Recommended Tool |

|---|---|

| Large-scale acoustic simulations | k-Wave |

| Rapid prototyping and parameter studies | k-Wave |

| Complex geometries (CAD imports) | COMSOL |

| Multi-physics with structural mechanics | COMSOL |

| GUI-based workflow preference | COMSOL |

| Teaching and visualization | Either |

Conclusion

Both k-Wave and COMSOL successfully simulate focused ultrasound heating, producing results that agree well with each other. Key findings:

- Multi-physics coupling: Acoustic-thermal simulations require careful coupling of the acoustic pressure field to the thermal heat source

- Thermal dose: CEM43 provides a clinically relevant metric for predicting tissue ablation

- Complementary tools: k-Wave excels in acoustic simulation efficiency, while COMSOL provides integrated multi-physics capabilities

Clinical Relevance

This simulation approach is directly applicable to:

- HIFU therapy planning: Predicting lesion size and shape

- Treatment monitoring: Correlating temperature measurements with thermal dose

- Device design: Optimizing transducer geometry for specific clinical applications

References

- Treeby, B. E., & Cox, B. T. (2010). k-Wave: MATLAB toolbox for the simulation and reconstruction of photoacoustic wave fields. Journal of Biomedical Optics, 15(2), 021314.

- Pennes, H. H. (1948). Analysis of tissue and arterial blood temperatures in the resting human forearm. Journal of Applied Physiology, 1(2), 93-122.

- Sapareto, S. A., & Dewey, W. C. (1984). Thermal dose determination in cancer therapy. International Journal of Radiation Oncology, Biology, Physics, 10(6), 787-800.

- COMSOL Multiphysics Reference Manual, version 6.4.

- Duck, F. A. (1990). Physical Properties of Tissue. Academic Press.